No.96-1 Qixin Road, Dongchong Town, Nansha District, Guangzhou, Guangdong, 511453, China

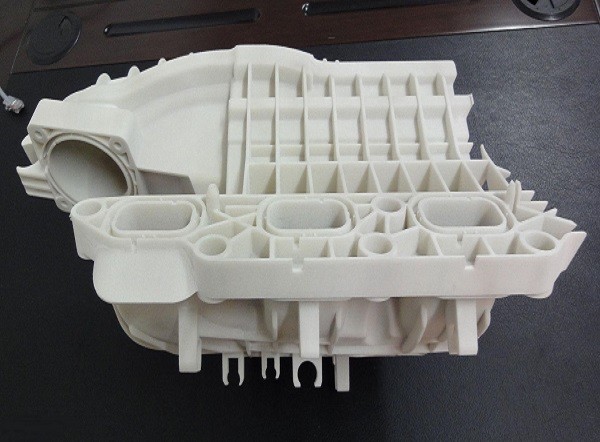

Plastics Solution

No.96-1 Qixin Road, Dongchong Town, Nansha District, Guangzhou, Guangdong, 511453, China

Pair the design flexibility of 3D Printing with the mechanical properties of metal. From production tools with internal channels to aerospace parts with latticed interiors, any metal application that involves complexity can benefit from Metal 3D Printing. Material:

1. Aluminum (AlSi10Mg)

Good strength and thermal properties with low weight

Flexible post-processing possibilities

2. Stainless Steel (316L or 1.4404)

Excellent strength, high ductility & good thermal properties

Highly corrosion-resistant

Vacuum Casting Materials

Rubber-like polyurethanes, ABS-like polyurethanes, PE/PP-like polyurethanes

High-quality surface finish comparable to injection molding

Sign up today for hints, tips and the latest product news - plus exclusive special offers.

We don’t do spam and Your mail id is very confidential.